Tuesday, 24 April 2012

BORDER WAR 4 - THE NEWCOMER 2012

Thursday, 19 April 2012

MOWING MACHINE OF TIKKAKOSKI

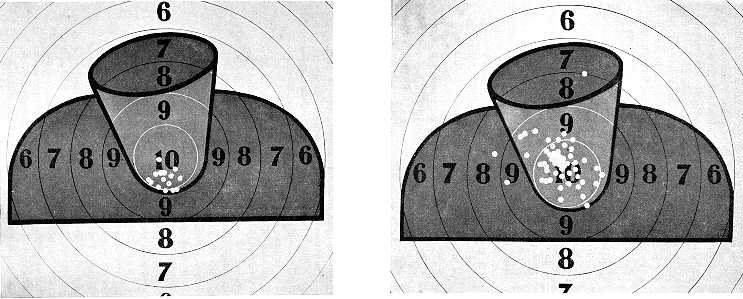

Muzzlebrakes or compensators are useless gimmicks on long-barreled submachine guns like KP/-31. Pressure of the muzzle blast is too low to generate reaction force strong enough to prevent "muzzle climb". A skilful submachine gunner can easily control the recoil and keep the gun steady, by keeping the thumb of his trigger hand behind the breech-cap. This thumb must receive whole recoil force. The butt of the gun is not allowed to hit or even touch shoulder of the gunner. Another way to control the recoil is to keep the gun with stiff hands, again without solid contact on the shoulder.

Photographs: J. Hartikka

According to the patent drawings most of the devices were too delicate and difficult to adjust correctly. The least complicated firing-rate reducer device, a simple vacuum valve, was used in every Suomi submachine gun since 1930 to ca. 1986, when last examples of this magnificent piece of equipment were assembled. Designers of "Pre-Suomi", A. Lahti, Y. Koskinen, L. Boyer-Spoof and their commanding officer captain V. Korpela, formed a company "Konepistooli Oy" ("Machine Pistol Ltd.") for submachine gun production.

The company Leskinen & Kari was able to make just a tiny batch of prototype guns (less than five handmade pieces) but tool-making Shop Tool Oy, in Helsinki, could make all the necessary equipment for production of machine pistols. A large industry hall was shared with another machine and toolmaking shop, Leonard Lindelöf Oy, which also made submachine guns, licensed copies of German Bergmann MP 18-1 from 1923 until 1932. During this time Lindelöf Oy could assemble only sixty (more or less miserable) copies of the MP 18, while Tool Oy made more than a hundred guns in the first years of manufacturing, from 1922 to 1925.

An adjustment of the cyclic rate was necessary because of readiness to adopt caliber 7.63 x 25 mm Mauser for export model submachine guns. The length of the breech-bolt stroke was just a bit more than the overall length of 7.63 mm Mauser or 9 x 25 mm Mauser "Export" cartridge. The Finnish Army, Frontier Guards and Civil Guard were satisfied with the less powerful but very accurate 7.65 x 21 mm Parabellum cartridge, which had been an official pistol caliber of armed forces since 1923.

The designer Aimo J. Lahti honed his invention to perfection during years 1930 - 1931. His intention was to sell the manufacturing rights of this Suomi submachine gun to the State of Finland, but the Finnish government had no manufacturing capacity in state-owned Valtion Kivääritehdas (VKT. Since 1946 VMT. Since 1950 until 1988 Valmet Oy/ Tourula Works).

Remarkable Innovations

The new owner of the manufacturing license, Tikkakoski Oy, was actually a multinational enterprise. The main stockholder was a German called Willi Daugs. The first shots discharged in anger were fired during the Gran Chaco War between Bolivia and Paraquay in 1932 to 1935. Apparently both belligerents possessed some Suomi submachine guns, either imported from Finland or captured. South America, the Baltic countries and Poland were objects of exporting effort before, and Sweden, Bulgaria, Denmark, Germany, Croatia and Switzerland during World War II. Manufacturing licenses were sold to Denmark, Sweden and Switzerland.

Lessons for whole World

Most Finnish-made guns were, however, bought for use by the Finnish armed forces. When the Russians tried to incorporate Finland into "the Big Happy Family of Soviet Nations" in November 1939, there were about four thousand submachine guns model KP/-31 ready for a hot salutation against unwanted liberators. This famous Winter War taught whole world to value of submachine guns as true instruments of warfare, not mere "emergency weapons for defense at close quarters for the personnel of specialist corps, such as motor transport drivers, spare numbers of machine-gun units, tank crews and head-quarter details." (Quotation from a British "Textbook of Automatic Pistols" by Robert Kenneth Wilson, written in 1935).

Most Finnish-made guns were, however, bought for use by the Finnish armed forces. When the Russians tried to incorporate Finland into "the Big Happy Family of Soviet Nations" in November 1939, there were about four thousand submachine guns model KP/-31 ready for a hot salutation against unwanted liberators. This famous Winter War taught whole world to value of submachine guns as true instruments of warfare, not mere "emergency weapons for defense at close quarters for the personnel of specialist corps, such as motor transport drivers, spare numbers of machine-gun units, tank crews and head-quarter details." (Quotation from a British "Textbook of Automatic Pistols" by Robert Kenneth Wilson, written in 1935).Construction of KP/-31

The words "robust" or "sturdy" capture the essence of the so called "first generation submachine guns" such as Thompson, Bergmann and Suomi. They were not yet spot-welded from sheet steel stampings and tubings, along with rough investment-cast main parts and brittle phenolic plastic components (called by disparaging name "gutta-percha parts" in Finland). The true Suomi, Konepistooli model 1931, is entirely made in Finland.

Milled from solid steel

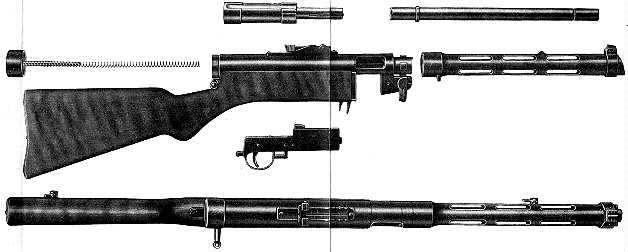

The rear end of the receiver is closed with a screw cap. Its seven threads are not interrupted, like those of Bergmann MP 18-I or 28-II. When field stripping and re-assembling the action of KP/-31, it is necessary to wind six to seven rotations of the cap while keeping the recoil spring compressed by pulling the cocking knob rearwards . The "hermetic" cap closure was found essential to assure proper functioning of firing-rate reducer or vacuum valve within the cap.

The rear end of the receiver is closed with a screw cap. Its seven threads are not interrupted, like those of Bergmann MP 18-I or 28-II. When field stripping and re-assembling the action of KP/-31, it is necessary to wind six to seven rotations of the cap while keeping the recoil spring compressed by pulling the cocking knob rearwards . The "hermetic" cap closure was found essential to assure proper functioning of firing-rate reducer or vacuum valve within the cap.Start of field stripping. Pull the cocking knob all the way backwards and while holding it, unwind the breech-cap (seven rotations counter-clockwise). IMPORTANT NOTE: The powerful recoil spring is fully compressed during winding and unwinding breech-cap! Keep your thumb on the center of the cap while rotating it with fingers of another hand.

It is necessary to to remove barrel jacket and barrel for routine maintenance, inspection and bore cleaning. Contrary to Bergmann MP's (to say nothing about Thompson), it is easy to remove even a red-hot barrel and install a cool spare barrel into front end of the receiver; just turn the jacket-key 90 degrees downwards and rotate the jacket 45 degrees to left, then pull the jacket forwards and loosen the barrel, also forwards.

Breech-cap and recoil spring removed. Note the rebated "bolt neck". KP/-31 is among the most reliable automatic firearms if the cartridges are faultless, the magazines flawless and the maintenance of mechanism is done scrupulously - without overdoing. As an example the inside of the receiver is not be lubricated but washed "bone dry" with gasoline or kerosene, especially in frosty weather, when the slightest amount of grease or oil may cause misfire or even a more serious accident. Contrary to a common misconception, shooting with an unlubricated gun does not cause wear of receiver or moving parts.

Breech-cap and recoil spring removed. Note the rebated "bolt neck". KP/-31 is among the most reliable automatic firearms if the cartridges are faultless, the magazines flawless and the maintenance of mechanism is done scrupulously - without overdoing. As an example the inside of the receiver is not be lubricated but washed "bone dry" with gasoline or kerosene, especially in frosty weather, when the slightest amount of grease or oil may cause misfire or even a more serious accident. Contrary to a common misconception, shooting with an unlubricated gun does not cause wear of receiver or moving parts.Q.D. Barrel Was Essential

was a rather expensive technical construction but actual fighting experience often proved it a successful barrel mounting method, compared with the thread mount of Bergmann or STEN and the fixed barrel of the Thompson. Many Finnish submachine gunners shot several thousand rounds during an hour or two, mowing down oncoming Russian hordes during the Winter War and the Finnish Third Independence War of 1941 to 1944.

was a rather expensive technical construction but actual fighting experience often proved it a successful barrel mounting method, compared with the thread mount of Bergmann or STEN and the fixed barrel of the Thompson. Many Finnish submachine gunners shot several thousand rounds during an hour or two, mowing down oncoming Russian hordes during the Winter War and the Finnish Third Independence War of 1941 to 1944.Removing a (cool) barrel and jacket is easy, compared with almost any submachine gun (save the OWEN). Turn the jacket latch or key down. Then, turn the jacket counter-clockwise while pulling it forwards. Once the jacket is removed, pull the barrel forwards out from the receiver.

Sometimes a single Finnish submachine gunner against a hundred Russians. At other times one gunner and a couple of magazine-filling assistants struggled against a full infantry company - 200 Russians - killing almost half of their troop and wounding many others. Some Finnish writers of war and remembrance novels say they have given too small numbers of Killed In Action enemy soldiers in their books because "nobody can believe my eye-witness' claim that one submachine gunner can slaughter eighty-five enemy soldiers during a skirmish lasting less than thirty minutes"..! Harsh facts are sometimes more incredible than fictions of novel writers.

If the jacket and barrel are hot after shooting it is advisable to protect the hand. A thin handkerchief is insufficient for this purpose after a discharge of twenty shots on automatic. A bullet of faulty cartridge stuck in the bore was the usual reason for barrel replacement during battle. According to the booklet "SUOMI-KONEPISTOOLI", published in 1942 by O/Y TIKKAKOSKI AB, it was allowed and safe to remove a stuck bullet by shooting with a full-powered cartridge. This harsh method was, of course, "for extreme urgency only". The primer of cartridge usually exploded during shooting away the stuck bullet, and the extractor disappeared after "duplex ball" shot, but the KP/-31 works well with no extractor at all. The thick-walled barrel easily withstood this misuse but it was necessary to remove the magazine and push the cartridge manually into the chamber.

In combat it was not unusual to shoot barrel and even the jacket of KP/-31 literally red-hot. If cleaning-rod was not at hand it was possible to turn the jacket loose with the edge of a puukko-knife and knock the barrel out with the point of puukko. Every Finnish fighter had (and still has) a knife with sheath as a multi-purpose tool, always hanging on his or her belt.

In combat it was not unusual to shoot barrel and even the jacket of KP/-31 literally red-hot. If cleaning-rod was not at hand it was possible to turn the jacket loose with the edge of a puukko-knife and knock the barrel out with the point of puukko. Every Finnish fighter had (and still has) a knife with sheath as a multi-purpose tool, always hanging on his or her belt. Bolt Chiming Like a Bell

The only Achillean heel of the bolt was the extractor hook which was made of spring steel but, like most well-designed automatic firearms with blowback action, the KP/-31 is able to eject spent cases without any extractor at all. It was just advisable to keep the gun on its right side, ejection port downwards, but this "mowing-fire hold" was natural to experienced gunners.

Firing Cycle

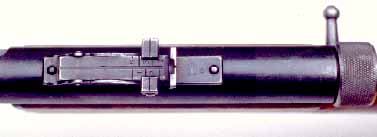

Top view of the receiver. The rear sight is graduated to 500 meters for harassment firing. Aimed shots could hit enemy individuals within 300 meters, but within distances of less than a hundred meters - common in skirmishes in afforrested terrain - the shooter simply pointed the gun in the direction of the enemy without aiming. Most skilled submachine gunners could operate their KP/-31 like a long-range shotgun, without the need of sights. A high rate of full-automatic fire had its uses.

"Differential Locking System"

The firing pin point, protruding 1.20 to 1.25 millimeters from the face of the flat bolt-recess bottom, dents the bottom of the primer and discharges cartridge, while the breech-bolt is still going forwards. The MOMENTUM of the bolt (MASS multiplied by VELOCITY) keeps the cartridge case immobile in chamber, until the peak pressure of the powder gases has lowered to ten per cent level from 2600 atmospheres (the allowable maximum chamber pressure of the 9 x 19 mm Luger cartridge). During the pressure peak the breech-bolt is still moving forwards, accomplishing the so called "differential locking" by combined weight and velocity, momentum.

Submachine Gun as a Small-Game Rifle

The trigger mechanism has no positive disconnector, like as that of the STEN or Bergmann MP 28-II, but if the original or spare bolt is fitted with skill and knowledge it is possible to shoot single shots with the KP/-31, one per a pull of the trigger at a rate of twenty to thirty aimed shots per minute - depends on the skill and experience of the gunner. During the Third Finnish Independence War (or the Russian Great Patriotic War - your choice) the KP/-31 was used as a hunting rifle in order to acquire some more meat in the form of forest birds and squirrels, thus making the diluted war-time soup more nutritive. An experienced hunter could easily hit the head of a squirrel from fifty meters if the sights of his Suomi-gun were adjusted "for his eye" and the barrel jacket was tightened to the receiver with one or two 0.10 millimeter thick steel washers.

These "accuracy jobs", hunting small-game animals or enemy officers, were the only instances when KP/-31 was used like a self-loading rifle, the shooter keeping the gun's buttstock firmly against his shoulder and making use of the sights for aiming. Full-automatic fire was usually just directed by instinct because smoke of pistol powder obscured the view ahead of the muzzle after the first or second shot of the burst. The vast majority of handgun powders contain potassium nitrate or other inorganic salts, being in fact just "semi-smokeless" propellants.

A Doctrine of Escalation

Semi-automatic shooting was the recommendation during the Thirties. The doctrine was to use the KP/-31 as a self-loading carbine and save the option of burst-fire for urgency only. The Winter War experience taught the submachine gunners to shoot bursts of two to three rounds and during the 1941 - 1944 war it was known that no fewer than five or six 9 mm bullets were a sufficient dose of medicine. Wounded with shorter bursts, enemy soldiers could often continue fighting when they recovered from the initial shock even if the hits would prove fatal after a short while.

"They were formidable opponents. We were urged to kill almost every Siberian twice, and most tough boys still a third time", told many Finnish veterans of wars: "Russian lads, coming against us in closed formation, intoxicated with vodka and singing Le Internationale, were bunny-boys but the Siberians were born soldiers! We met them in February 1940 and we learnt to respect those slant-eyed imps... !" Two bullets were enough for "bunny-boys" but five hits were necessary to dispatch a Siberian "imp". Sometimes they fought back despite ten or twelve wounds from 9 mm bullets.

A true "vanity of vanities" is a little round aperture or a "magazine window", stamped through the bottom of the magazine and the numerals 1 to 40 stamped on the feed plate. In theory it was possible to check the number of remaining cartridges from the window. In practice the stamped figures were very difficult to see even in daylight, and dust or dirt had entrance through the window to jam delicate parts of the magazine. Excessive lubrication made things still worse. A seventy round magazine was planned to be developed using a staggered-row feed groove principle, but the 70 rd. drum m/Koskinen was found to be superior in reliability and cost-efficiency.

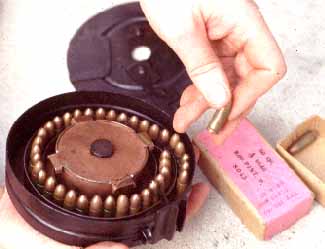

Drum m/Koskinen

Ltn Koskinen introduced his magazine in 1935. On January 28, 1936 Tikkakoski Oy received an order from the Finnish Army Ordnance Department for 8000 drums m/Koskinen. Follow-up orders were for 20 000 drums in April 1936 and for 21 000 magazines in January 1937. A sufficient quantity for the four thousand KP/-31 used during the Winter War, and one answer to question "How come Finland could stand while Poland, the Baltic republics and France all fell in some weeks, days or hours ?" Men behind guns and guns in the hands of men did their duty..!

Ltn Koskinen introduced his magazine in 1935. On January 28, 1936 Tikkakoski Oy received an order from the Finnish Army Ordnance Department for 8000 drums m/Koskinen. Follow-up orders were for 20 000 drums in April 1936 and for 21 000 magazines in January 1937. A sufficient quantity for the four thousand KP/-31 used during the Winter War, and one answer to question "How come Finland could stand while Poland, the Baltic republics and France all fell in some weeks, days or hours ?" Men behind guns and guns in the hands of men did their duty..!

A filled seventy rounds drum "M/Koskinen" after winding the mainspring (two full rotations, eight clicks of the ratchet). The inner and outer feet grooves hold 35 rounds each.

If more than 35 cartridges are loaded into the magazine these are placed in the outer feed groove. The inner groove is fastened on a rotating feed-plate. A steel clip, projecting outward from the plate, pushes cartridges from the outer groove to the lips of magazine and stops the rotation of the feed-plate when the outer groove is empty. The remaining 35 cartridges now start to flow into gun through the feeding lips.

Loading the 50 rd. box magazine, known as "ruumisarkku"; the coffin. A loading tool is essential to push in the recommended 40 to 45 cartridges. With the tip of a screwdriver it is possible to squeeze some thirty rounds into the "coffin", and with bare fingers presumably no more than ten cartridges.

Sweden adopted a shortened variation of the KP/-31 for manufacture under licence as the Kulspruta or Maskinpistol Model 37-39 and bought full-size guns from Finland as the model 37-39 F. The Swedes were not satisfied with the 70 rd. drum, finding it overly complicated, expensive and too heavy compared to its cartridge capacity. Apparently the Swedish firm Linde AB designed a novel, four-row 50 rd. box magazine that was 40 per cent lighter in "dead weight" compared to the 70 rd. drum m/Koskinen.

The Swedish magazine is composed of two staggered-row box magazines with a common feed "throat" tapering to feed lips, similar to all earlier magazines of KP/-31: The distance between the lips is considerably less than diameter of a cartridge case. Filling the magazine is therefore slow and tedious, even with a special filler tool (any user of the STEN gun will probably concur with this statement)

The magazine followers of the Swedish 50 rd. "coffin magazine" are of cast aluminium alloy, presumably too soft a material for the purpose because the feed springs are truly heavy. The springs are tapered and it is possible to compress them down to a very small space thus keeping the overall length of the magazine not much longer than that of the 20 rd. box clip. The Finns were fascinated by the light weight and inexpensive manufacture of this magazine.

250 Swedish magazines were bought before the Winter War for tests by military units. In 1940 Tikkakoski Oy bought the manufacturing licence for the "coffin magazine", but feed springs for them were bought from Sweden until the end of production. 120 000 Swedish pattern 50 rd. magazines were made by Tikkakoski Oy in the years 1941 to 1943. By then the many drawbacks of mechanism had became well-known: the magazine is impossible to fill with much more than ten cartridges without a special tool. This in itself was not a rare defect but battlefield experience had revealed some other drawbacks as well.

The balance of the feed springs was critical and the Swedish springs were sometimes of varying quality. It was possible to wrongly re-assemble the magazine after field-stripping. Feed jams were met frequently if the magazine was filled up to full 50 rd. capacity. A reasonable quantity of cartridges is 40 to 45 rounds (this author has shot ca. 3000 rounds using "coffin magazines" usually filled with 25 and never more than 30 cartridges. No feed jams or other disorders were apparent. This author has, of course, filed and honed away all the sharp burrs from the feed lips).

The magazine was also too frail to stand knocks or battering. A slight bruise or a small quantity of dust or dirt inside a loaded magazine could render it unserviceable. The manufacture of the Swedish pattern 50 rd. magazines was terminated in 1943, when the technical superiority of the Finnish 70 rd. drum had - once again - been demonstrated.

36 Rounds Box Magazine

After the Second World War there were more than sixty thousand of KP/-31 delivered to Finnish armed forces, along with 10 000 submachine guns m/-44 (Finnish copies of the Russian Pulemyot Pistolyet Sudayeva m/-43). Magazines, including drums, were the same for both models. Huge quantities of magazines were worn out or lost during the war. For example Finnish ranger patrolmen classified the 40 rd. drums as "disposable magazines" or "throw-away drums ". Empty drums were actually thrown away because they were almost impossible to refill during battle. In the first years of the Fifties there were only two or three magazines for each gun.

A Suomi KP/-31 SJR and another specimen with a Barrel Unit SS-II. Just a lack of perforations in the jacket and compensator may reveal the difference... until actual shooting! The magazines are Lapua-made 36 rd. boxes "M/55".

A Suomi KP/-31 SJR and another specimen with a Barrel Unit SS-II. Just a lack of perforations in the jacket and compensator may reveal the difference... until actual shooting! The magazines are Lapua-made 36 rd. boxes "M/55".The formerly German-owned Tikkakoski Oy was occupied by Russians and made only sewing machines and vacuum cleaners. The know-how and machinery for manufacturing of drum magazines was under the control of the Arch Enemy. It became necessary to adopt an entirely novel type of magazine.

The famous Swedish Carl Gustaf Model 1945 submachine gun had a box magazine "m/45 B", capacity 36 rounds, with mounting rails similar to those of the 50 rd. "coffin magazine". A new and interesting feature was the wide "mouth", which enabled easy filling of the magazine by pushing cartridges down, sideways. No special loading tools are necessary. The pressure of the feed spring was just reasonable - no longer excessive. The strength of one's fingers was usually sufficient to fill the magazine with 30 to 35 cartridges without undue effort. The length of the magazine "m/45 B" is 225 millimetres and the width 25 mm.

The magazine was found to be as durable and reliable as the 70 rd. drum but much less expensive to manufacture. The first Finnish copies were made by Ammus Oy in 1954. The run of batch was, fortunately, only a hundred magazines; They were made carelessly and without all the necessary know-how. Swedish-made sample magazines, bought for the sake of comparison, were found to be of good quality and their price was much lower due to steady mass production.

The Swedish manufacturer AB Linde Kvarnmaskiner offered their magazines. They were officially adopted for use by the Finnish Army on December 21, 1954 as magazine "m/54", and AB Linde received an order for 50 000 magazines from Finland one week later. This quantity was but one fifth of the needed quarter of a million 36 rd. magazines. The Lapua Cartridge Factory now offered to manufacture 200 000 magazines similar to the model m/54, at a competitive price. The General Staff of the Finnish Army placed an order on March 5, 1955.

The Lapua-made 36 rd. box magazine is the "model/55". Technically it is similar to Swedish "m/54", with the addition of a steel-wire carrying loop. The quality of the Finnish-made magazines "m/55", kept in depots for emergencies, is excellent and they are usually sold to collectors in auctions or from Army surplus shops in mint condition. Conscripts trained as submachine gunners during the Sixties and early Seventies (including this author) received two battered 70 rd. drum magazines along with their government issue KP/-31. In 1967 there were 65 rounds of bulleted cartridges issued for the training of each submachine gunner during seven months' military service. The magazine well of almost every KP/-31 was widened for the "m/55" magazine before the early Seventies as a part of routine maintenance.

Variations and Special Models

Receiver, breech-bolt and trigger mechanism are unchanged in all variations of KP/-31, save rare prototypes made for intended Persian export. These had top-mounted box magazine, without option for use of drum magazines. Bipod was usual outfit. "Persian model" was called as KP/-33. (Persia is nowadays known as Iran). At least one variation of KP/-33 was furnished with a pistol-grip and quickly-detatchable wooden butt, like Thompson submachine gun.

The receiver, breech-bolt and trigger mechanism are unchanged in all variations of KP/-31 save some rare prototypes made for intended Persian export. These had a top-mounted box magazine and no option to use drum magazines. A bipod was usually fitted. The "Persian model" was designated the KP/-33 (Persia is nowadays known as Iran). At least one variation of the KP/-33 was furnished with a pistol grip and a quickly-detatchable wooden butt, like that of the Thompson submachine gun.Some guns model KP/-31 were also equipped with a bipod and a pistol grip, mounted between the trigger-guard and the magazine well. These gimmicks were soon found to be unnecessary.

The muzzle brake of the KP/-31 SJR was troublesome in frosty weather. Solid powder and primer residue could become trapped in the chamber of the projecting compensator and reflux thru the bore into the receiver. The sticky mass of condensed water, carbon and salts could literally paste onto the snugly fitting breech-bolt, causing misfires and accidental firing.

Misfire outdoors in the cold could release the breech-bolt from the grip of the sear and, if the gun was then warmed, when a loaded magazine was mounted, it might suddenly fire when the residue holding the breech-bolt thawed. It was not just advisable but strictly mandatory to remove the magazine from a "frozen" submachine gun before any attempt to melt the breech-bolt loose by warming or shooting a cartridge, loaded manually into the chamber, was made. As soon as possible it was essential to field-strip the gun and clean its receiver, breech-bolt and compensator.

The enraged A. J. Lahti attempted to find out who the inventor of the compensator was and to have him charged in a military court, but to this day the identity of the "genius" responsible remains strictly classified. Despite these well-known risks the Finnish Army ordered all new Suomi guns with the SJR device beginning in 1942. On the other hand the Civil Guard demanded normal short jackets for guns ordered for their members until 1944 when the Russians forced the government of Finland to suppress the Civil Guard.

Muzzles of KP/-31, KP/-31 SJR (with compensator), "Korsu-Suomi" (with flattened "vacuum cleaner nozzle"), "Tank-Suomi" and Barrel Unit SS-II, silenced variation model 1995.

Muzzles of KP/-31, KP/-31 SJR (with compensator), "Korsu-Suomi" (with flattened "vacuum cleaner nozzle"), "Tank-Suomi" and Barrel Unit SS-II, silenced variation model 1995. The phrase "any Guardian is a better authority on firearms than all Finnish Army generals" was not just an idle boast. Some sources have called the KP/-31 SJR the "model -31/-42". This designation is incorrect and misleading because there was an independent "model 1942". Just a few prototypes of the KP/-42 were made. Despite the many improvements upon KP/-31 it was impossible to adopt a new model during the war. (There are no rules without exceptions: The KP/-44 or "sheet-steel submachine gun", also known as the "Tin Henry", a short-cut from expensive first generation gun to cheap third generation gun).

The improvements of the KP/-42 were: Less expensive fastening of the wooden stock by a Martini-Henry screw; less expensive but more durable sights; a front sight with protecting "ears" and a firing-mode selector returned to the right side of the gun.

The "Korsu-Suomi"

This Bunker Suomi or pill-box gun is a highly specialized weapon for shooting through the narrow, horizontal firing slits of hemispherical steel bunkers, the so-called "Mannerheim's helmets", and concrete bunkers built along the so-called Mannerheim Line.

This Bunker Suomi or pill-box gun is a highly specialized weapon for shooting through the narrow, horizontal firing slits of hemispherical steel bunkers, the so-called "Mannerheim's helmets", and concrete bunkers built along the so-called Mannerheim Line.The "Korsu-Suomi" Bunker Gun is almost as long as the normal KP/-31 with a butt stock because of an extra-long barrel jacket, necessary to funnel powder gases out from the bunker. The barrel length of all Finnish-made versions of KP/-31 is 314 mm, the only exception being the new Barrel Unit SS-II.

Shooting with a normal KP/-31 thru a ca. one inch high firing slit was difficult - if not impossible - and even unhealthy. It was impossible to use sights and powder gases threatened the gunner with nitrogen oxide or carbon monoxide poisoning. The shoulder stock of the KP/-31 was also an inconvenient and useless component for a bunker gun.

The design of the Bunker Gun was begun in August 1939. Before the Winter War there were two lengths of "duck-bill" barrel jackets with fixed, side-mounted sights and a welded frame for a pistol grip . Experience indicated the longer jacket (435 mm) was better than the shorter one (385 mm) for eliminating muzzle flash and evacuating powder gasses from the bore before opening the breech-bolt between shots.

Before Finland's Third Independence War the construction of the pistol grip was simplified so that it was possible to mount either a normal stock with shoulder butt or a pistol grip with a forked tang to receiver of gun. The first phase of the 1941-1944 war was, however, a Finnish invasion of the most favorable positions for defence against Russia. 500 jackets of the Bunker Suomi were mounted on receivers with full-length stocks. Although there were no front sights above these jackets the submachine gunners could soon master their guns without any use of sights at all, just like well-trained skeet-shotgunners.

The "Tank Suomi"

This model is not an entire gun but a combination of a firing port jacket and pistol-butted KP/-31s. The jackets were mounted on Finnish tanks, of the Christie or Vickers type, and the Bunker Gun was mounted in that jacket just before driving towards the battlefield. If the tank crew was forced to fight dismounted, after the destruction or a less permanent immobilization of their armoured vehicle, it was possible to leave the barrel jacket into firing port of the tank or armored car and to fix a normal KP/-31 jacket to the gun.

The "Tank Suomi" is among the most rare variations of the KP/-31. Only 31 jackets, serial numbered along with pistol-grip submachine guns, were assembled in July 1940. No further submachine guns with firing port jackets were needed because the Russians brought the Finnish tank corps a more than sufficient quantity of Degtaryeva Tankovoy machine guns during the Winter War. These 450 DT tank machine guns (of caliber 7.62 x 54 mm Russian) easily displaced Tank Suomi guns. There were more than six Tankovoy machine guns for every Finnish armored vehicle. Surplus DTs were issued to infantry units, equipped with bipod and sights. Our photograph shows the presumably only privately owned Tank Suomi submachine gun jacket.

"Ancient? Obsolete?"

Finnish Army conscripts look at the Suomi submachine gun KP/-31 with the same curiosity as they would a steam locomotive or a gramophone in a technical museum. The assault rifle is today the general-purpose instrument of the Finnish armed forces. An unknown quantity of submachine guns is still stowed up in depots but many of them are being sold to collectors. Spare parts and unfinished forgings have also been made available. The KP/-31 was found to be "ancient" in 1944 but obsolete it has become only in the Nineties.

As a fighting instrument in forested terrain the KP/-31 is still fully serviceable because the engagement distance is usually less than a hundred meters. However modern doctrine favors a one caliber system of ammunition as far as is possible. The assault rifle is able to do the duty of a submachine gun. So why carry two kinds of individual firearms with different cartridges?

The Last Model

The availability of unperforated, semi-finished forgings of barrel jackets made possible the creation of some prototypes of the Barrel Unit "Model SS". The abbreviation comes from "Suhina-Suomi" (Sighing Suomi). The barrel of the SS-II Unit is shortened and drilled through walls like the barrels of the STEN Mk II S or the Welrod Hand Firing Device, to lower the pressure of powder gas in the bore and to slow down the bullet velocity below Mach 1, the speed of sound. The barrel jacket of the SS-II Unit forms the outer casing of the integral sound suppressor a.k.a. silencer.

The "Suhina-Suomi II" suppressed barrel unit mounted to a "Korsu-Suomi".

The "Suhina-Suomi II" suppressed barrel unit mounted to a "Korsu-Suomi". The unit is of a telescopic construction. Twenty cupped baffles, similar to those of famous Maxim Silencer, are stacked into the front end of inner suppressor sleeve. This sleeve is fastened by a threaded cap into the jacket and is removable as one part.

The barrel is centered into the sleeve by a perforated support and a solid septum. A snugly fitting shoulder in front of the barrel flange centers it into the jacket. Powder gas, bled from barrel perforations, fills the space between the sealing shoulder and the septum known as the "blowback intensifier chamber". The bullet, emerging from the muzzle, flies through the stack of baffles. The muzzle blast hits the conical diffractor and the curved reflector, refluxing to an expansion chamber around the barrel.

When the bullet emerges from the mouth of the suppressor, powder gas is trapped in the expansion chamber and into the spaces between the baffles. This part of the gas flows slowly out of the suppressor mouth with a muffled "sigh". Another volume of gas, trapped into the blowback intensifier chamber, escapes into the bore through barrel perforations. The rapid reflux of the gas accelerates the rearwards movement of the breech-bolt.

The component parts of the Barrel Unit are enclosed in the jacket which may be mounted onto any KP/-31. The use of a slightly shortened recoil spring may be necessary in order to avoid uncontrolled fire when shooting the least powerful factory-loaded cartridges or subsonic handloads made for guns with a traditional muzzle-can suppressor. The mechanical noise of a suppressed KP/-31 is conscipiously low due to the heavy steel construction of the receiver and the noise-absorbing, wooden stock.

Old soldiers never die and firearms designed to be "everlasting" do not fade away easily.

The First Independence War of Finland was a civil war between patriotic Finnish people and Bolsheviks, the so-called Red Guard. Both sides were aided by Russians. Russian Bolsheviks donated armament to the Reds and general Carl Gustav Emil Mannerheim, the leader of the victorious Civil Guard or White Peasant Army, was also an officer of the Imperial Russian Army before the October Revolution of 1917.

The Independence War broke out on January 23, 1918 and the Bolshevik Mutiny on January 27. The White Army and auxiliary troops from the Imperial German Baltic Sea Division liberated southern Finland in a couple of weeks before a never-to-be-forgotten triumph parade in Helsinki on May 16, 1918.

It was the first time when a heroic Finnish people stopped the Great Red World Revolution but it would not be the last one. Vengeful Russian Communists, along with Finnish Bolshevik refugees residing in Soviet Russia, tried to conquer Finland in two weeks starting on November 30, 1939.

Finland stood alone but our people were able to stand and struggle until March 13, 1940. This war is known as the Winter War or 105 Days of Glory in Finland, but as a Disgraceful War in Russia since 1988. (In the earlier Soviet Union's history writing this campaign was almost entirely forgotten). Both Finns and Russians knew that the armistice after the Winter War was nothing but a frail truce.

Some days after the start of the German "Operation Barbarossa" the Russians begun air-raids against more than twenty densely populated communities in Finland. In late June 1941 it was realized that a state of war existed between Soviet Russia and Finland. As an ally of Germany Finland was able to conquer the territories lost to Russians after the Winter War and push still forwards to more favorable defensive positions.

This Third Finnish Independence Struggle became a kind of trench warfare by the late 1941 or early 1942. On June 10, 1944 when the Germans were obviously already losing the Second World War the Russians were able start a massive attack on Finnish troops. The retreat of the Finnish armed forces ended in July or early August 1944. The Russians were suffering huge losses of military forces, ordnance and transport, including armored vehicles, due to Finnish defensive actions. The wave of Worldwide Red Revolution was once again broken on the rock of the determined Finnish people, once again supported by the Germans - just as during the last weeks of the First Independence War of 1918.

Third Independence War of Finland (so called by the then President Risto Ryti in 1941) is usually known as the Continuation War, because it was an inevitable continuation of the Winter War, which in itself was a continuation of the Independence War of 1918. This third war against Red Russia ended on September 5, 1944 but the Second World War was not yet over in northern Finland. The last phase of it was an "infamous war" against the Germans retreating from that area of Finland.

The Finns were unwilling to harass their former comrades in arms but it was Red Russia which dictated the rules of Finnish politics from September 1944 until August 1991, the bitter end of that Reign of Wickedness. The shameful war in Finnish Lapland was over on April 27, 1945, less than two weeks before the end of WWII.

There is no reliable evidence to confirm whether submachine guns were used in the 1918 war. The production of the Bergmann MP 18-I had just been started in April 1918 and all guns were needed in the European trenches. The Winter War taught the whole industrialized world to appreciate submachine guns. Sir Winston Churchill would never again scorn the Thompson gun as a "tool of American gangsters, unfit for use by honest Britons". In fact he begged from the U.S.A. as many Tommy Guns as the Auto Ordnance Company could assemble.

Adolf Hitler, a veteran of the First World War, knew better than any other influential statesman the importance of submachine guns. He pressed German designers to improve the existing MP 38 so that it would be more suitable for mass production. The simplified MP 40 met these requirements.

Adolf Hitler, a veteran of the First World War, knew better than any other influential statesman the importance of submachine guns. He pressed German designers to improve the existing MP 38 so that it would be more suitable for mass production. The simplified MP 40 met these requirements.Bergmann MP28-II (above) and MP 40.

During the Winter War the Soviet Russians possessed just as many submachine guns as their Finnish opponents; they had about 4000 guns of two or three different models. They were made like expensive "de luxe" shotguns and were therefore unfit for use in cold weather. So they were returned to arms depots.

In 1941 Georgiy Shpagin designed a very succesful second generation gun which was suitable for inexpensive mass production and much more reliable in winter warfare than any other contemporary submachine gun. Many Germans adopted PPSh -41 guns for their own use because captured 7.62 x 25 mm cartridges were plentifully available from Killed In Action Russian gunners or conquered ammunition depots.

The reliable functioning of the Pulemyot Pistolyet Shpagina fascinated the Germans, especially when a freezing Russian winter halted the first phase of Operation Barbarossa. Chilly weather also made supply lines difficult to travel. The supply of Russian ammo was lot more plentiful and assured than the availability of 9 mm Luger cartridges for German MPs.

The large capacity of the drum magazine was also found to be more useful than the 32 rds. box clip of German submachine guns and the cyclic rate of fire was twice as high as that of the MP 40. The PPSh -41 shot sixteen or seventeen bullets per second, while the MP 40 shot only seven or eight. The high cyclic rate was beneficial for mowing down large, dense hordes, "human waves" of Russians.

The wooden butt of the PPSh -41 was also more comfortable to keep against the cheek than the collapsible steel stock of the MP 38 or 40, especially in cold weather. The German designer Hugo Schmeisser developed a hybrid model MP 41, with the action of the MP 40 but a wooden buttstock of the earlier Bergmann MP 28-II. A patent litigation brought about the discontinuation of the MP 41. The action of the MP 38 and MP 40 was designed by Heinrich Vollmer of ERMA GmbH, which was the plaintiff in the case. The manufacturer of the MP 41 was Waffenfabrik C.G. Haenel of Suhl.

The Haenel firm was found guilty of patent infringement and obliged to cease the production of the Maschinenpistole MP 1941 by the judgement of the Berliner Kammergericht (= Chamber Court; a least authoritative court in Germany). A great triumph of bureaucracy...! Heinrich Vollmer was undeniably the designer of MP models 38, 38/40 and MP 40 (usually called Schmeisser), but Hugo Schmeisser was the inventor of the submachine gun with blowback action.

Some Finnish warriors also adopted captured PPSh -41 guns during the offensive phase of the 1941 -44 war. 7.62 x 25 mm cartridges were plentily available from killed Russians and captured ammo depots or baggage. When the cartridges ran out "Pepesha guns" were simply thrown away or delivered to Army depots. Many warriors brought disassembled PPSh to their homes as souvenirs but this practice soon became too risky. In early 1942 one daring private attempted to bring home a disassembled Russian 50 mm mortar in his knapsack. He was caught and after this unfortunate incident soldiers headed for home on leave found their luggage more carefully examined by "lousy War Dogs" (Military Policemen).

Heaps of captured PPSh guns were stocked in depots. At one point there were plans to modify them to use 9 mm Luger ammunition by replacing the barrel and shortening the space between the "jaws" of the magazine well to that Finnish magazines could be used. This modification was soon found to be too difficult to accomplish. The Russian 7.62 mm Tokarev cartridge is five millimeters longer than the 9 mm Luger cartridge and Finnish magazines were accordingly less high. It was possible to narrow the magazine jaws by splitting the receiver into two parts, milling and welding the parts together again. However the welding weakened precisely the least durable place of the receiver. (Nobody realized that Russian magazines feed 9 x 19 mm cartridges without a hitch, despite the cartridge's shorter length !)

Making 9 mm barrels also proved to be a troublesome task, not a simple re-drilling and re-rifling process. The barrel had to be removed from the combined unit that was the barrel, jacket and upper receiver. The hard-chromium plating of the bore was destructive to drill bits. The enlargened bores too often became crooked and/or too large and rough. Only a handful of PPSh guns had been equipped with Finnish-made 9 mm barrels by the time the modification project was discontinued as impractical.

Despite the limited production capacity the numbers of the Suomi KP/-31 were increased to meet the demands of Finnish armed forces. There are some similarities between the KP/-31 and PPSh -41 such as magazine capacity, cyclic rate of fire and the wooden buttstock. The Finnish gun is, however, a first generation submachine gun while the PPSh is a typical second generation submachine gun: Mass-produced for a massive army, and thus possessing neither quickly detachable barrel nor some other luxuries such as versatility with very slight - if any - alteration of the receiver mechanism.

Friday, 13 April 2012

Deutsches Liedes

Just one reminder,please:those who cannot refrain themselves on calling such period songs as "nazi propaganda" are advised to think twice.Most of the Wehrmacht music was already there when war started,and still are deep embedded in the current German folk & historic music,and songs such as,say,"Lili Marleen" is still treasured not for its (obvious) meaning of soldiering,but for its charm it renders to German folk.

My point?The songs here are not displayed as Nazi propaganda,nor were they collected and uploaded by me to this purpose or in support of NSDAP or any other doctrine or / and ideology.They are a piece of history,and a part of an unclear and sometimes muddy past which some of us try to understand!Thank you!

Gloria Viktoria

Preussens Gloria

Panzer Voran

Markischer Heide

Lili Marleen

Lied der Panzergrenadier

Grunn ist unser Fallschirm

Es ist so schon Soldat zu sein

Erika

Die Wacht am Rhein

Das U-boot Lied

Das Stuka Lied

Wenn Wir Marschieren

Luftwaffe Lied

Thursday, 5 April 2012

So you want to impersonate a German Heer?

Basis of impression

Pictured here is an enlisted soldier of an infantry unit in the Heer (army), mid-late war. He is wearing an M40 wool feldgrau uniform with infantry collar tabs and shoulderboards. Our soldier is wearing the Heer chest eagle and the insignia of a low-ranking NCO – an Obergefreiter. The red medal ribbon shows that he has served on the Eastern front. His M35 helmet is fitted with a splinter pattern cover and a foliage loop made from a tyre inner tube: a field improvisation enabling soldiers quick and easy camouflage to break up the lines of the distinctive helmet.

He is armed with an MP40 sub-machinegun, with the six spare magazines carried in a pair of pouches that hang off the standard German belt. Note that the Heer belt buckle (normally silver in colour) has been painted grey/green to lower its visibility – a common practice by this stage of the war – and that he carries a stick grenade for quick use at the front of his belt. To support the increasing weight of the belt order – also carrying breadbag, mess tins and water bottle – leather Y-straps are worn, with the gas mask tin on a canvas strap and also attached to the belt. It should be noted that by this stage in the war most soldiers had “lost” the gas masks that were supposed to be in the tin, and they tended to be used for the carriage of additional ammo, food and personal effects. At the rear, attached to the top of the Y-strap is a rolled-up Zeltbahn, a large triangle of cloth which served as a tent quarter, a rain cape, or was worn over the feldgrau uniform as a camouflage smock. Like most Heer camouflage items, it is in splinter pattern.

The other noteworthy point about this Heer soldier is that he is wearing boots and gaiters, a wartime economy measure, though senior NCO’s and Officers often still had their old-style jackboots.

Head

• M35 Helmet: £45 – EB (EM, MN, RAU, NM, SoF)

• Splinter/white reversable helmet cover: £14 – MN (EM, EB, RAU, NM, SoF)

Uniform

• M40 Pattern Tunic: £40 – SH (MN, EM, EB, RAU, NM, SoF)

• M37 Pattern Trousers: £30 – SH (MN, EM, EB, RAU, NM, SoF)

Insignia

• Collar insignia: £10 SoF (MN, EM, RAU, NM, RS)

• Chest eagle: £4 – SoF (MN, EM, RAU, NM, RS)

• Feldgrau shoulder boards with white edging: £10 MN (EM, RAU, NM, SoF, RS)

Feet

• German low boots: £75 – EB (NM, EM, SoF, RAU). (Cut down British Army boots are a cheap alternative.)

• Repro gaiters: £4 – ZP (EM, SS)

Belt Order

• Leather belt: £20 – MN (EM, SoF, RAU, NM)

• Heer Belt Buckle: £15 – MN (EM, RS, SoF, RAU, NM)

• 2 x MP40 magazine pouches: £25 – SoF (EM, MN, RAU, NM)

• Leather Y-straps: £30 – MN, (EM, SoF, RAU, NM)

• Bread bag: £12 – SS (MN, EM, SoF, RAU, NM)

• Mess tins and strap: £5 – ZP (SS, EM, MN, RAU, NM, SoF)

• Water bottle and cover: circa £40 – EB (EM, SoF, RAU)

• Gasmask Tin and straps £50 – SoF (MN, EM, RAU, NM)

• Zeltbahn quarter: £32 – MN (SoF, EM, RAU, NM)

• Zeltbahn straps: £4 each – MN (EM, SoF, RAU, NM)

Weapons

• ACM MP40: £100 – AH (RSOV)

• MP40 Sling: £12 – MN (EM, SoF, NM ,RAU)

Notes

All prices stated are approximate. Those in brackets are alternative suppliers, who may be more expensive. Often, shopping in the far east can be a false economy, since you are hit with high postal charges and (sometimes) import tax – and the quality of goods may be lower than that of the good UK suppliers, such as Militaria-Net or Richard Underwood.

Key to retailers

MN: Militaria-Net (UK) http://www.militaria-net.co.uk

EB: eBay.co.uk (UK) http://www.ebay.co.uk

EM: Epic Militaria http://www.epicmilitaria.com

RAU: Richard A Underwood (UK) http://www.richardaunderwood.com

ZP: Zeltplane_Com (eBay) (GER) http://myworld.ebay.co.uk/zeltplane_com

SH: Spearhead (eBay) (HK/Singapore) http://myworld.ebay.co.uk/barrylyndon28

SoF: Soldier of Fortune (UK) http://www.sofmilitary.co.uk

RS: Regalia Specialist (UK) http://www.nicholasmorigi.com

RSOV: RSOV (HK) http://www.rsov.com

AH: Action Hobbys (UK) http://www.actionhobbys.co.uk

(Copyright goes to http://www.ww2airsoft.org.uk/german-heer-infantry/)